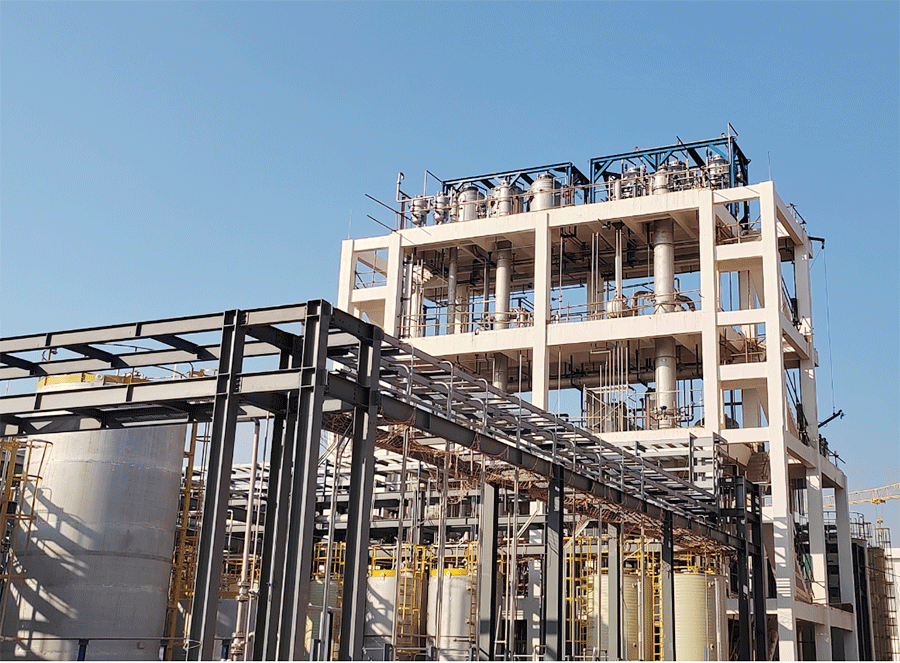

Demo Project in Guangxi Province: Extractive liquid ORZ high-efficiency oil removal treatment

Publish Time: 2024-12-13

1)Project Investment: 50-60 million yuan (RMB)

2)wastewater capacity: Nickel sulfate production wastewater:1400M3 per day, Manganese sulfate production wastewater 240M3 per day, Cobalt sulfate production wastewater 240 M3 per day

3)Oil content index: Influent oil content: ≤50mg/L, Effluent oil content: ≤3mg/L

Technology advantage:

It can remove dissolved oil in liquid, and the oil content after degreasing is ≤1 ppm.

Avoid the abnormal operation of evaporation process due to bubbling of the material liquid.

"Zero loss" - no adsorption of inorganic substances, no loss of raw materials and valuable metals.

The system is safe and stable, and the operating cost is low.

"Zero pollution" - resource recycling of ethanol, water, oil, etc., no secondary pollution such as hazardous waste.

The whole system has a high degree of automatic operation, which can realize "unmanned workshop"

Scope of application:

ORZ high-efficiency oil removal technology is widely applied to the deep oil removal of organic phosphoric acid extraction systems such as P204, P507, C272 and BC196 in nickel cobalt and rare earth industries, as well as the COD removal of raffinate and the deep impurity removal of reverse raffinate. It has a remarkable effect especially on refractory dissolved oil.

So far, more than 10 projects have been established for technology and equipment, and the annual wastewater treatment volume is about 4.05 million tons, the maximum treatment scale is 1.31 million tons per year in a nickel sulfate liquid oil removal project.